blown film machine parts name

ISHAN Multilayer Blown Film Extrusion Machine. What are the components of the film blowing machine.

Software Architect Creates An Amazing Ultimaker 2 Aluminum Extrusion 3d Printer 3dprint Com The Voice Of 3d Printing Additive Manufacturing 3d Printer Aluminum Extrusion 3d Printing Machine

The traction auxiliary machine is composed of main comp The traction auxiliary machine is composed of main components such as traction frame herringbone plate traction roller take-up mechanism and traction motor.

. Arlington Machinery offers blown film equipment winders industrial printer parts film die and blown film lines and more new and used blown film equipment for. This bubble is sustained by air and is fed up through a scaffold where the tube continues to rise. Blown film machine parts name Thursday March 17 2022 Edit.

Complete tutorial of mini film blowing machines - from startup to stable operationThis is a relatively long video about 10 minutes. The traction motor of this unit adopts. 3 layer blown film machine.

Blowing film involves a delicate balance of forces which are primarily controlled with the air ring lip settings. What is Blown film Extrusion process in Hindi Blow ratio Draw Down Ratio PlasticsWorld alokrj cipet This video is for BTech BSc CIPET students. The main motor may have frequency control of motor speed to improve speed regulation and save electricity.

Screw and barrel motor inverter heaters die head winder and tower. First step plastic pellets are put into the extruder and heated to their melting point at 180 to 210 Celcius degree. We are producing blown film lines since 1967 and have consistently set new standards such as the development of the internal bubble cooling system and the oscillating haul-off.

Please slide to verify. Open the catalog to page 10. Blown Film Machine Parts Find Details about Heat Shrinkable Film Machine 1 Layer Blown Film Machine from Blown Film Machine Parts - WENZHOU.

Our blown film portfolio offers the right machine for your individual production needs. Lldpe monolayer blown film plant 15-35 kw production capac. The plastic is then forced through a cylindrical die and forms a thin walled bubble.

3 Control over the angle and expansion of the main flow of air from the upper lip enabling adjustment of the low-pressure region that results in bubble lock. Screw and barrel motor inverter heaters die head winder and tower. 2 Components Of The Film Blowing Machine 2 Components Of The Film Blowing Machine An Introduction To Single Screw Extrusion Blown Film An Overview Sciencedirect Topics Plastic Extrusion What Is It How Does It Work Process.

The blown-film process involves extruding a relatively thick tube which is then expanded or blown by internal air pressure to produce a relatively thin film. The tube can be collapsed to form double-layer layflat film or can be slit to make one or two single-layer film webs. Hdpe high speed blown film plants.

Ad High Quality Film Blowing Machine with Competitive Price. 2 A suitable expansion angle leading to the upper lip and. Vikas industries plastic monolayer blown film extrusion mach.

At Rajoo the metamorphosis was quick. These lines are extremely energy efficient and give optimum production rate which makes investment to installed capacity ratio much favorable. Film Blowing Machine Accessory.

Ad High Quality Fast Processing For Blown Film Processors. Cost-saving efficient high output plastic recycling machine PP HDPE LDPE LLDPE blown film machines pellet machines and. 3s enterprises fully automatic compostable bag making machin.

It all began in 1986 and the last 25 years have witnessed the transformation of a modest beginning in a relatively unknown town of Manavadar. Ocean international blue white three layer blown film plan. Before the delivery of t.

WH blown film lines are designed especially for the flexible packaging industry. The screw and material barrel may be made from a nitrogen-treated chromium-molybdenum-aluminum alloy. Over 30 Years Experience.

They are designed for highest quality resource efficiency and profitability and set. Sorry we have detected unusual traffic from your network. The process of blown film is reasonably simple.

5 Layer Blown Film Co-ex Line Highly versatile die design leading to optimum quality of Barrier as well as Facilitates optimisation of Tie Layer Blown Film Co-extrusion Lines In Technical collaboration with. Superior Performance For Your Extrusion Line. WINDSOR MACHINES LIMITED Formerly DGP Windsor India Ltd 5403 Phase IV GIDC Vatva Ahmedabad.

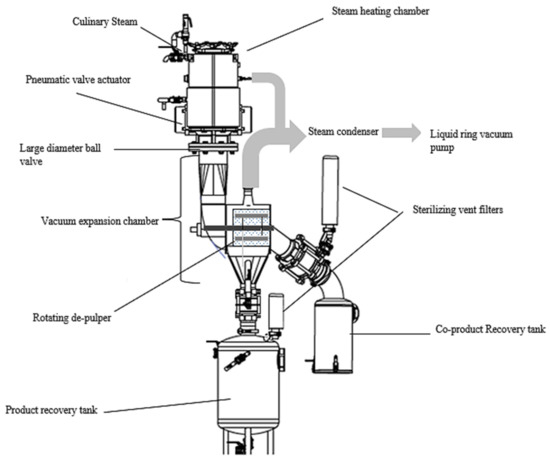

Innovative Food Processing Technologies

Rotational Movement An Overview Sciencedirect Topics

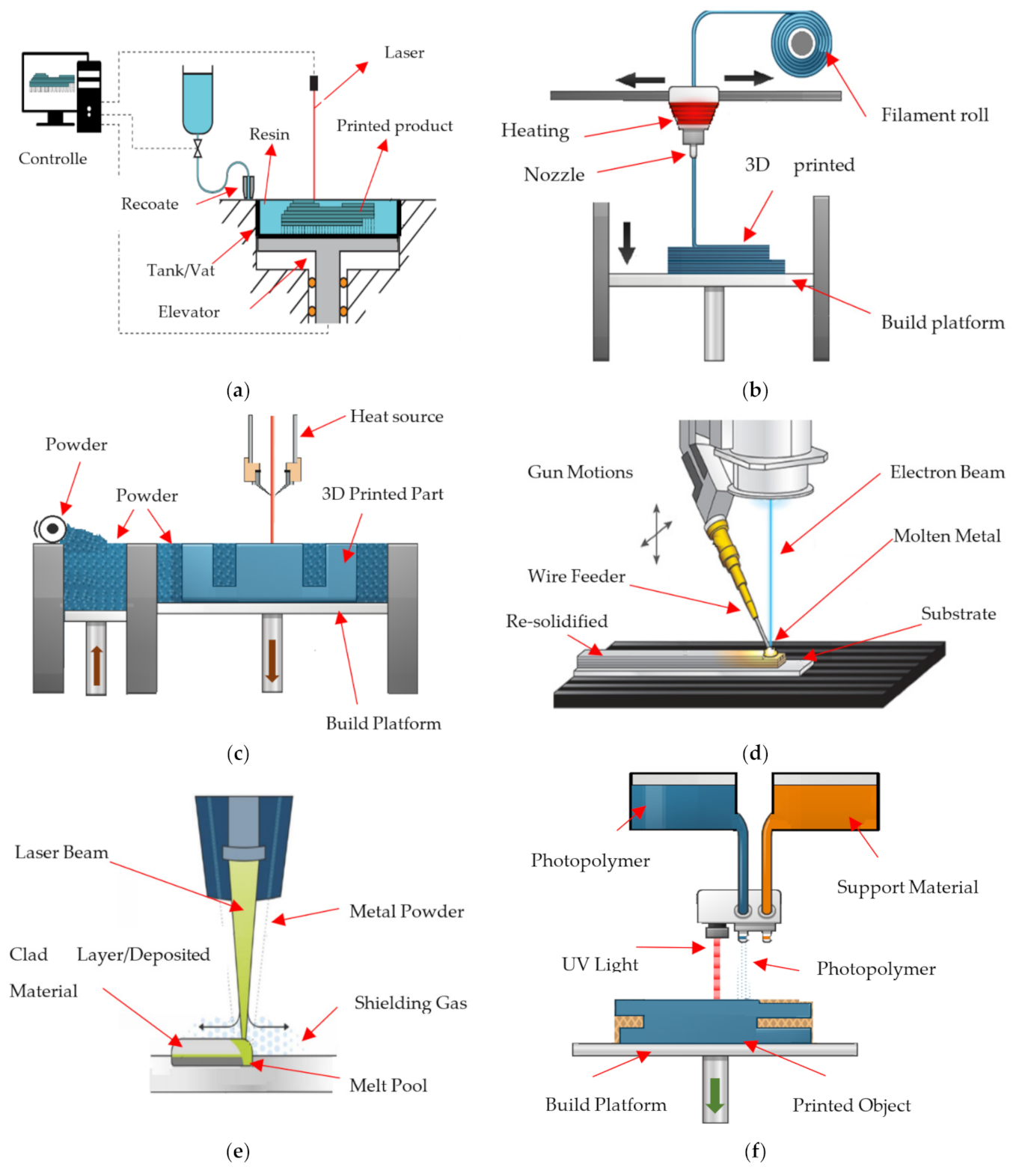

Applied Sciences Free Full Text Advances In Metal Additive Manufacturing A Review Of Common Processes Industrial Applications And Current Challenges Html

Tutorial Injection Molded Parts

Edm Machining Components Types Applications And Advantages

Shaper Machines Definition Parts Working Types Operations Shaper Machine Machine Definition

Ox Cnc Machine Mechanical Kit Etsy Cnc Machine Cnc Router Plans Cnc

Coextrusion An Overview Sciencedirect Topics

Automatic Rings Sealing Machine Rotary Glass Jars Sealer Equipment With Caps Lifter Feeding System Rotary Capper Equipment Shenzh Industrial System Blueprints

Pin By Chris On 5 Axis Cnc 5 Axis Cnc Cnc Floor Plans

Cold Forging Press For Auto Spare Parts Hydraulic Press Machine Auto Spare Parts Forging

Efficient Enough To Produce Bottles Blow Molding Molding Blow

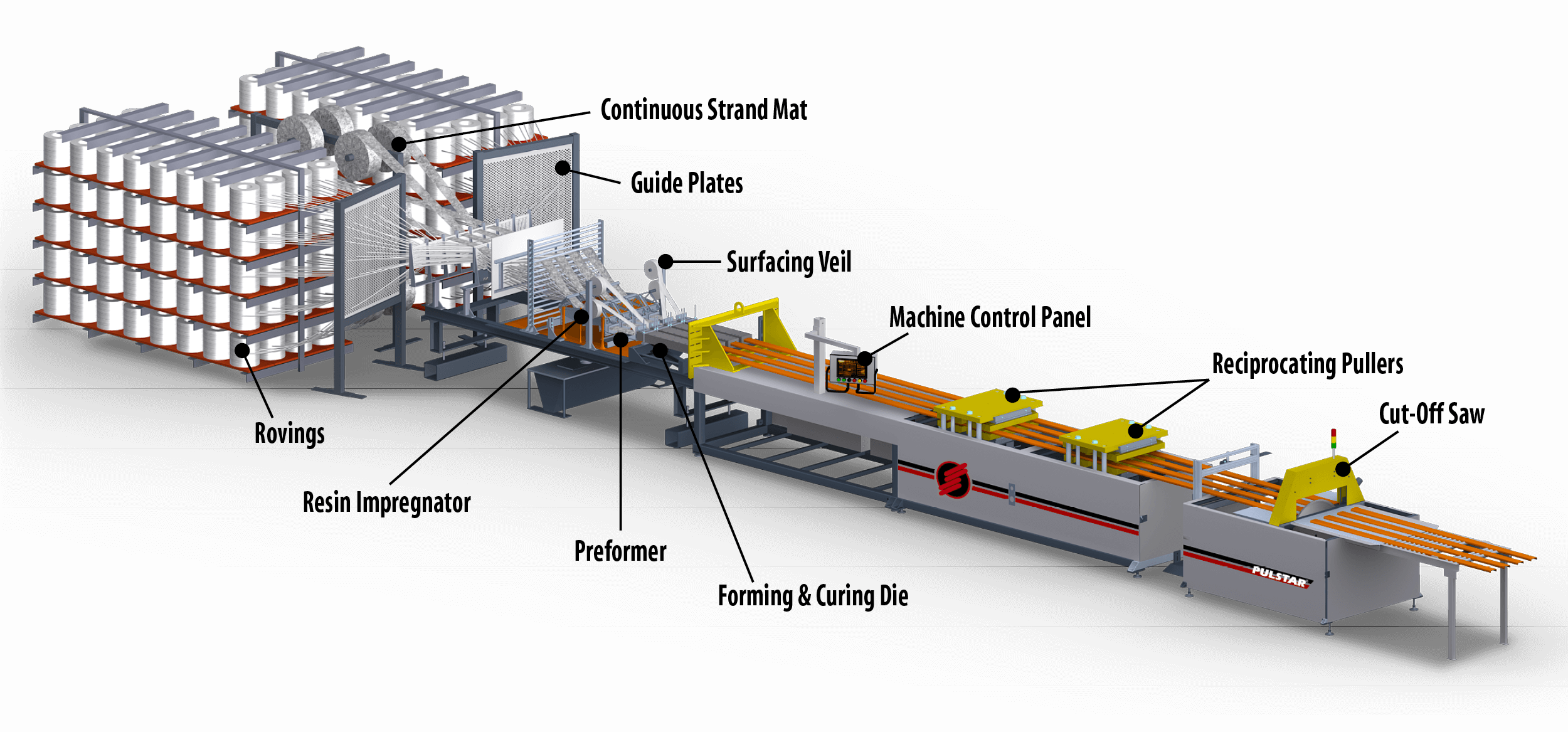

Pultrusion Industry Pultruded Fiber Reinforced Polymer

Open Source Print Head For Clay Stoneflower Stoneflower 3d Clay Extruder 3d Printer 3d Printing Business